Dalkita’s pragmatic approach is more than just green labels. Our focus is to design and plan in a way that limits energy use, limits waste, and creates projects that are able to successfully and smoothly operate within their environments for years to come.

Distilleries can be huge consumers of energy.

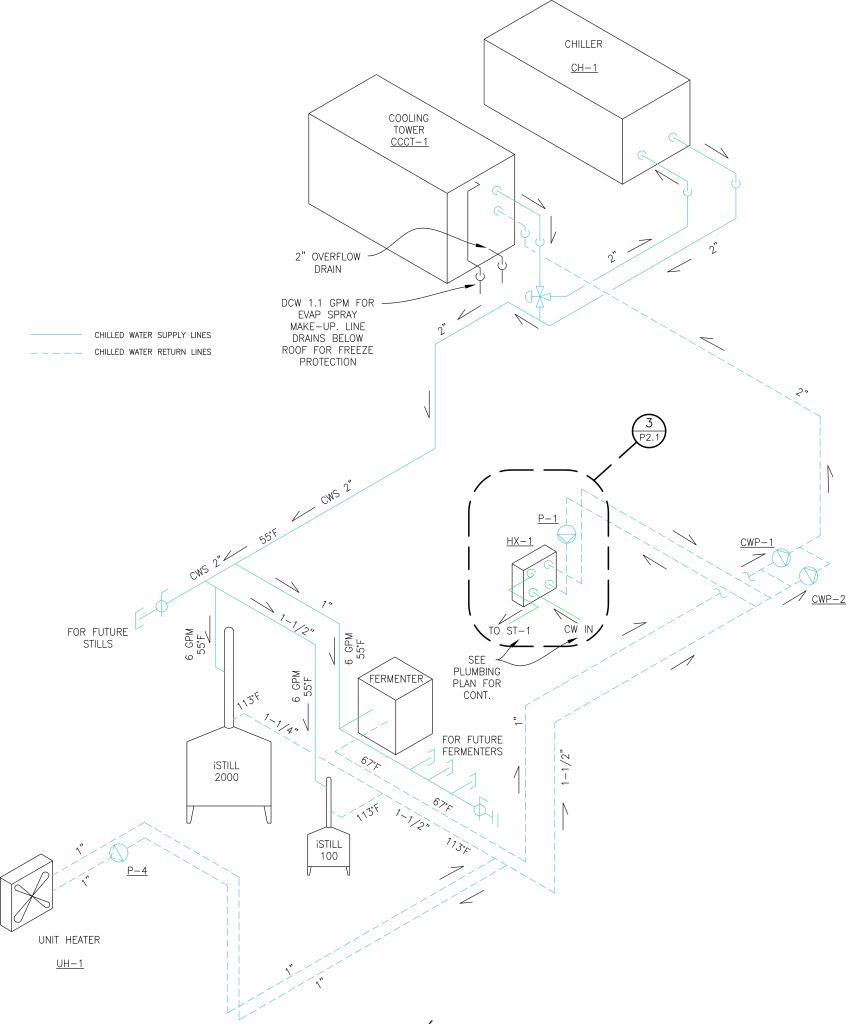

Electric stills, boilers, water heating, process cooling, building space heating and cooling. Much of the excess heat produced by equipment can be re-used elsewhere, rather than wasted.

Much of the excess heat produced by equipment can be re-used elsewhere, rather than wasted for example. Heat from still to be used for domestic water heating, other process heating, snowmelt systems, and building heat.

Many distilleries require high levels of exhaust air to ensure a safe working environment.

Exhausted air from distilling spaces must be sent directly to the outside. But, we can consider where makeup intake air is coming from. Often distilleries have adjacent functions, such as tasting rooms, which require a high level of outdoor fresh air. So, we can re-use the air from the adjacent use in the distillery before it is exhausted. This way, the tempering of air (heating /cooling) is being utilized twice, instead of simply being brought into the distillery, heated or cooled, and then exhausted.

Here are our top five cost-effective and simple ways to achieve energy efficiency in a custom mountain home…